high quality mechanical seal for slurry pump factories

Latest articles

- Keeping clean catch basins clean from solids

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreDefinition of dredge and slurry pumps

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreSlurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreSlurry Pump

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreThe terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read MoreIs the discharge configuration suitable for abrasive slurries?

high quality mechanical seal for slurry pump factories...

high quality mechanical seal for slurry pump factories 【high quality mechanical seal for slurry pump factories】

Read More

Popular articles

- Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

- Working principle

- If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

- What is slurry?

- >Slurry Pump VS Mud Pump

- Some models can generate discharge pressures up to 260 ft. (80 m).

Latest articles

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

-

Selecting And Operating A Slurry Pump

-

Mill sump

-

Slurry pipe diameter.

-

Typical Applications of slurry pump

-

Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

Links

- One of the key features of Flex Tape in white is its incredible adhesive strength. Once applied, it forms a tight seal that is waterproof, UV resistant, and can withstand extreme temperatures. This means you can trust Flex Tape to keep your repairs secure and long-lasting, no matter the conditions.

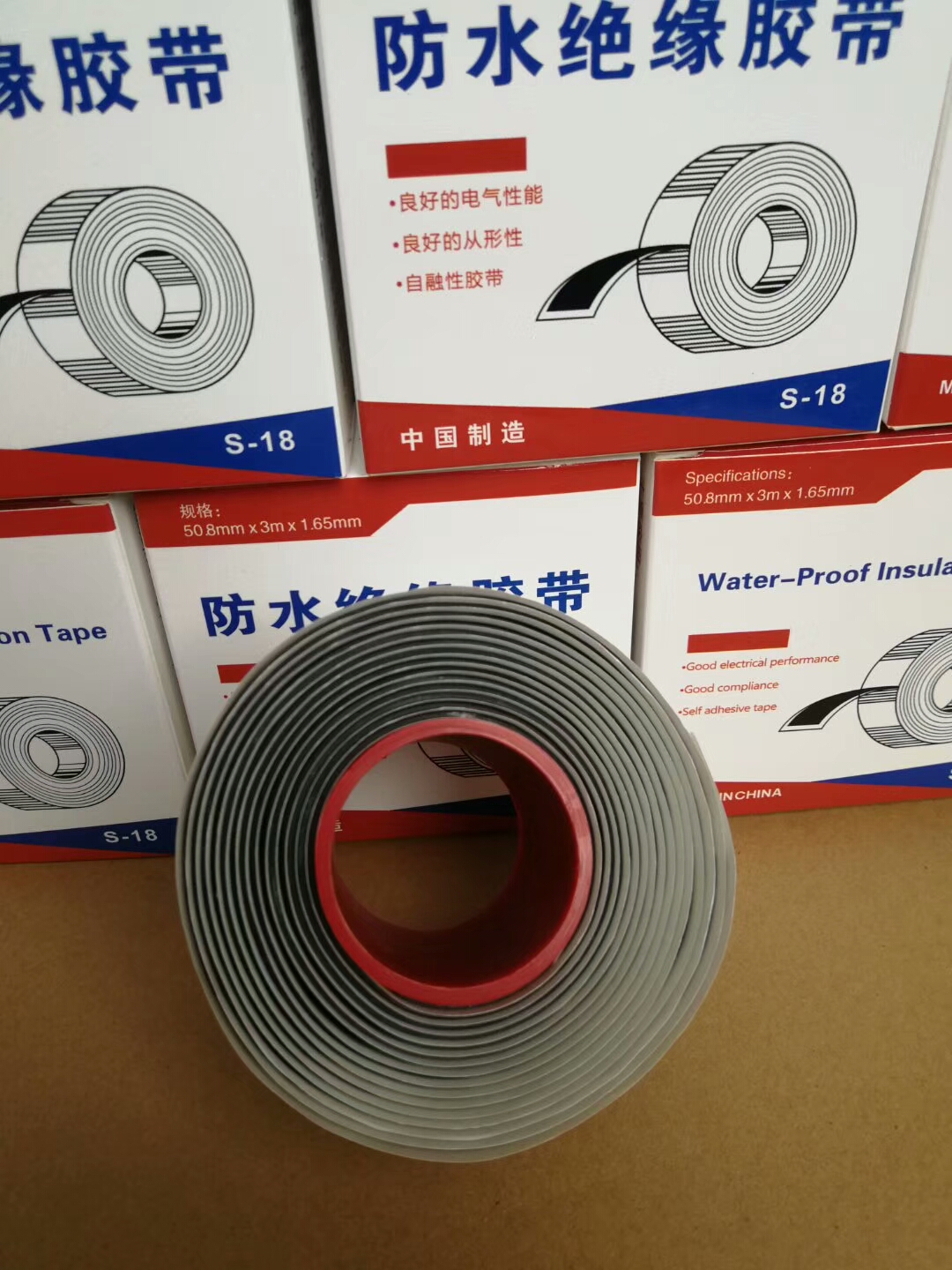

When working with electrical tape, it’s important to make sure that you’re using the right kind for the job.

- Flex Seal Tape The Ultimate Solution for Sealing and Protecting

Some common applications of butyl rubber tape include using it for window and door installations, sealing gutters, fixing automotive leaks, and even in HVAC systems to create airtight seals. In the construction industry, contractors often use it for flashing around windows and roofs to prevent leaks during construction and in finished structures.

Polyethylene film tape (63535) is a 7-mil thick tape coated on one side with a synthetic rubber adhesive. This particular tape is UV-resistant and can form a water-tight seal, making it a good tape for outdoor use. It is designed to be able to mask windows and doors in stucco fabrication and other construction applications. This tape is available in white or red. Available widths range from 2 inches (48 millimeters) to 44 inches (1,118 millimeters).

One of the primary uses of black PVC tape is for electrical insulation. It is commonly used by electricians to wrap and insulate exposed wires, preventing electric shocks and short circuits. The tape's flexibility allows it to conform to various shapes and sizes, ensuring a snug fit around cables and connections. Furthermore, its strong adhesive properties ensure that it adheres securely, minimizing the risk of it peeling away over time. The tape can withstand high temperatures, making it ideal for both indoor and outdoor electrical applications.

By adhering to building codes and employing fire seal tape, builders and developers demonstrate their commitment to safety. Regular inspections and maintenance of fire seal tape can also ensure that it continues to perform its function throughout the life of the building.

Electricians have critical jobs. Keeping our world powered requires concentration, knowledge and skill. Some of the most dangerous work is done by electricians working on medium and high voltage applications. Ethylene propylene and silicone rubber electrical tapes have the highest dielectric rating of electrical tapes made by 3M and are a trusted product in the toolbox of most medium and high voltage linemen and installers. With proper wrapping, their self-fusing properties help to eliminate voids in critical areas that may cause catastrophic failures .

Silicone tape is renowned for its waterproof properties. It is an ideal solution for sealing leaks in boats, outdoor equipment, or even temporarily fixing damaged gutters during heavy rain.

Repairing vacuum hoses or joints

splicing tape use. This ensures a smooth and consistent print job without any breaks or interruptions. Similarly, in the packaging industry, splicing tape is used to join the ends of rolls of film or other packaging materials to create a continuous stream for packaging machines to work efficiently.